Aluminum brazing under controlled gas atmosphere (CAB) CAB - Chargenofen

Since 2000 sellacan sold more than 70 Batch-Type-Furnaces world-wide (Status 2018) and offers a product perfected, well introduced to the market and of high interestdue to the following benefits: :

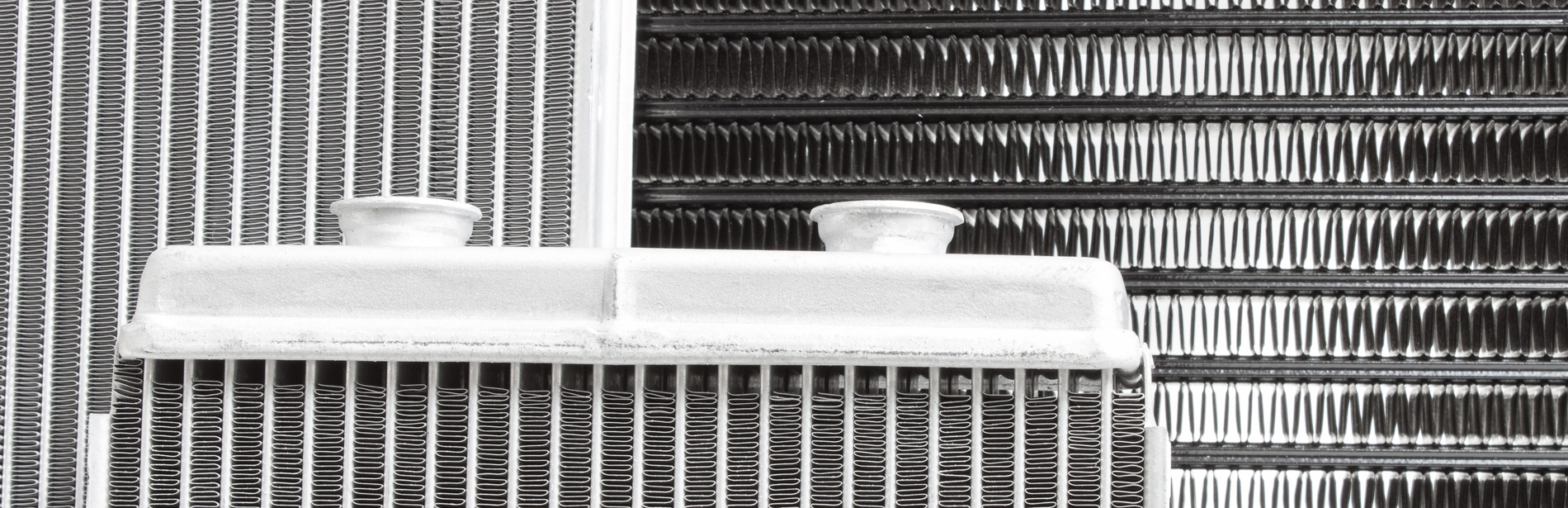

• Variable use of different types of heat exchangers (size, weight, type). Capable of XXL dimensions

• Vertical brazing (CAC, Oil Cooler, P&B) as well as horizontal brazing in the same furnace

• Easy change of different types of cores to braze

• Start-up equipment for newcomer in aluminum brazing

• Suitable both for trial runs as well as development of heat exchangers

• Appropriate for high-output production

• Vacuum locks provide a better change of atmosphere inside the cores

• Low energy consumption, simple stand-by operation and short heating-up time

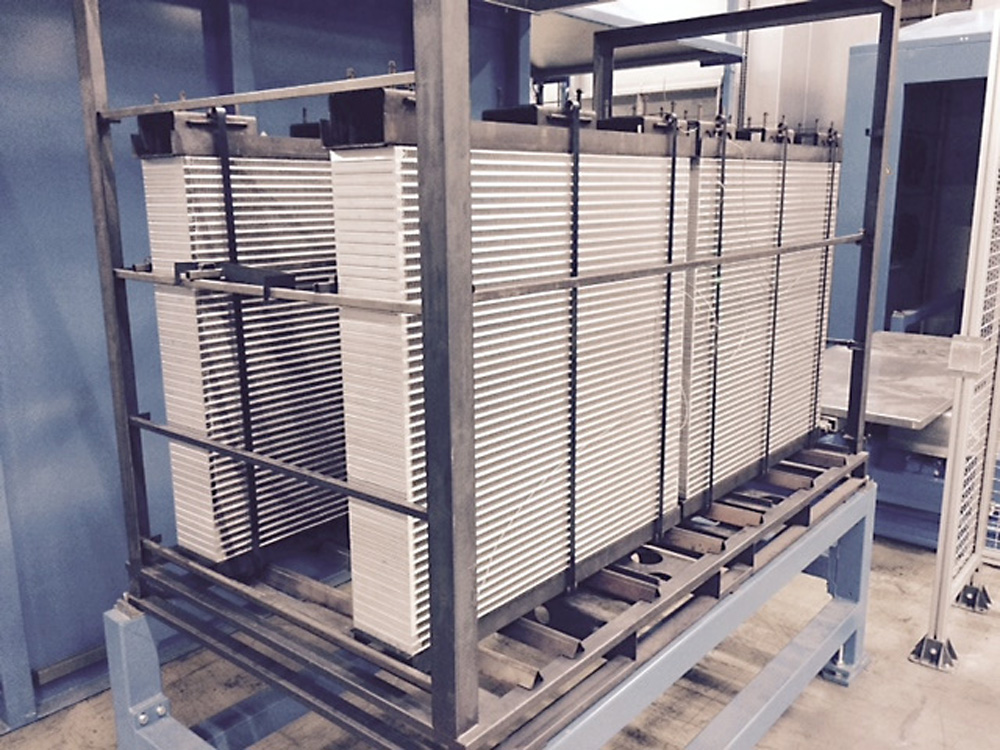

• Increased batch size with dimensions 1.300 x 1.000 x 2.300 mm or 1.300 x 700 x 3.150 mm (h x w x l)

• Sliding tables for batch weight of up to 750 kg gross

• Semi continuous production by automatic rack circulation.